Food Contamination can be harmful to consumers. Plus, it’s an embarrassment to the company. Cross-contamination also leads to wasted food sources and loss of revenue. That is why it is essential to take the proper steps to clean and sanitize food preparation areas. Drains can easily be overlooked, but wastewater contains particles that serve as a food source for the microbes that live in dark damp places, like drains. Things like movement, splashing, and airflow can result in cross-contamination that leads to unclean food.

Implementing a Plan

The best practices for cleaning and sanitation are education, documentation, and testing. Know how many drains need to be attended. Insure employees understand the best practices for floor and drain cleaning. Make sure all drains are accounted for and maintenance with a plan that is documented. It is also important to follow up with regular testing to ensure that practices are being followed correctly and drains are up to par with safe practices.

What is the best method to clean and sanitize drains?

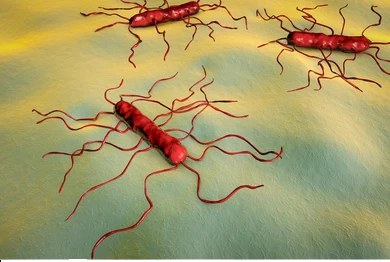

Bacterial Growth E. coli, Salmonella, staphylococcus aureus, and listeria are examples of potentially dangerous bacteria that thrive in drains. Listeria is a particular problem because it can continue to grow even in refrigerated and frozen environments. Clogging, standing water, and dirty drains are most prevalent reasons for bacterial growth. It is less likely to find these contaminants in drains that adhere to regular cleaning and sanitation.

Drains are an important part of every workspace and home. They are vital to remove liquid waste to a facility where it can then be treated. When drains are not maintained to a necessary level, they can become clogged and non-functional. When drains clog it causes pooling, foul odors, and the risk of contamination rises. When drains get backed up it becomes an immediate problem that must be fixed. Professionals must be called in, food production is stopped, and the costs outweigh those of regular maintenance.

Summary

Drain maintenance should be considered a necessary part of cleaning and sanitation. Operating by a schedule, with the correct cleaning materials, and procedures is the healthy practice that prevents illness and saves valuable resources. There are a lot of consequences that arise from dirty drains, and maintenance is the best possible way to avoid them.