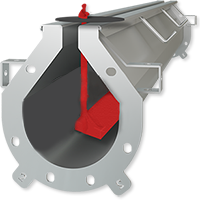

Drain Rings®

Time‑release cleaning agents that help prevent buildup, clogs, and odors in round floor drains.

Learn more →Controlled Release Technologies has time-release solutions, like Drain Rings® and Trench Clean®, help prevent clogs, support sanitation, and keep production moving, while our HVAC treatments protect coils and drains in air-handling systems.

Our controlled‑release drain treatments and coil care products integrate with your PMs to keep drains clear and coils cleaner. The result: fewer surprises, safer floors, and easier audits—without slowing production.

Support uptime in production, packaging, and cold‑storage areas.

Time‑release cleaning agents that help prevent buildup, clogs, and odors in round floor drains.

Learn more →

Designed for linear trench drains in food plants, releasing cleaning agents over time to help reduce buildup and odors.

Learn more →

EPA‑registered time‑release rings & blocks to help keep HVAC condensate pans clear and odor‑free.

Learn more →

Formulations for routine coil maintenance that support heat‑exchange efficiency.

Learn more →

Thin protective coatings designed to resist fouling and help sustain performance between cleanings.

Learn more →“Since adding Drain Rings and Trench Clean, we’ve reduced daily drain cleanouts and odors around production. Our PM team now spends less time fighting backups and more time on proactive work.” Maintenance Manager — Ready‑to‑eat facility

We’ll recommend products, quantities, and schedules for your drains, lines, docks, and cold rooms—and provide the documentation you need for audits.

CRT products are formulated for use in building drains and HVAC systems and are not intended for food‑contact surfaces. Follow your facility SOPs/HACCP plans and always consult product labels and SDS.

Yes. We provide SDS, spec sheets, and product labels. We can also help standardize SKUs and PM schedules across areas to simplify audits.

Most plants operate on 30–90 day drain cycles and periodic coil maintenance based on load and environment. We’ll help set a schedule that fits your facility.